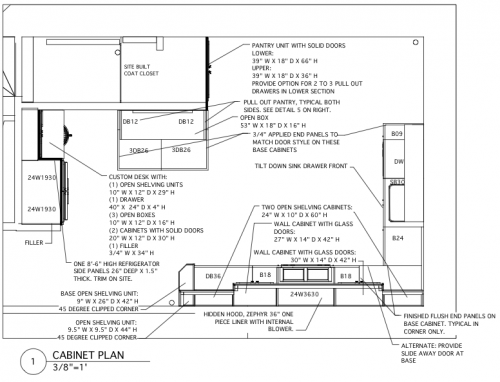

We recently began a full-scale renovation of this Flourtown kitchen. At the outset of the project, the homeowner explained to us that the existing space had been renovated about 10 years earlier, but it didn’t retain its value and hadn’t worn well during that time. What began as a relatively straightforward kitchen replacement project, however, soon became complicated by some unforeseen issues that we found once we opened up the walls. Luckily, our experience has equipped us with a few solutions to most problems we come across, so we were able to identify and correct the issues to bring them into compliance while keeping costs under control. What’s more, this customer is very knowledgeable about the systems in her home, so she understood that these were important fixes, and she could visualize how the multiple steps would come together.

What we found:

Problem #1 – The second-story bathroom drain pipe was too high within the framing of the kitchen floor below. The framing didn’t allow room for that drain pipe, which requires a certain amount of height to maintain the pitch of the drain. This was caused by poor pre-planning when the structures were originally built. A higher floor framing member would have provided enough room.

Solution #1 – Working around that pipe, we packed up the subfloor, installed a new hardwood floor, and instructed the cabinet installer to cut out some space in the back of the cabinet toe kick to accommodate the pipe.

Problem #2 – The walls and ceiling contained some unsafe wiring. In addition, because there were a number of circuits in the kitchen, a sub-panel was required, but the existing one in the kitchen was an eyesore.

Solution #2 – We worked with our electrician to relocate the sub-panel to the utility area of the basement and to clean up unsafe wiring and junction boxes with new wiring to code.

Stay tuned for updates on this project as it unfolds…