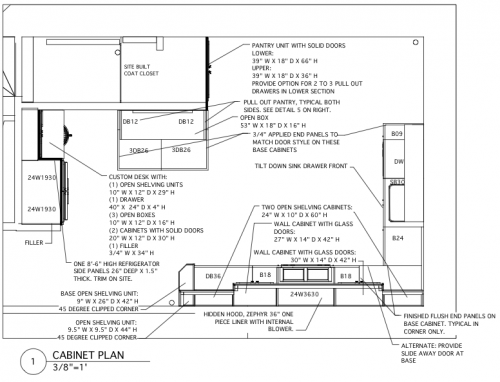

At this point, the custom cabinet designer and installer have been out to our Mt. Airy kitchen project site three times to fine tune measurements, and they will come out at least once more to complete the process. This is after many dozens of drawings, e-mails, and telephone conversations between them and our designers. Meanwhile, the cabinets are being made in sections in Bucks County, 60 minutes away from our job site.

The design detail with this type of high-end bespoke cabinetry is so fine that we have to adjust our drywall layout and window installations to ensure that everything fits seamlessly. Using various computer design programs and the skill of the designers and fabricators sets us up for a successful outcome.

The floor-pouring sub is also on site sanding and touching up the floor to make it flat and level. Before the final floor is installed, the Marmoleum sub will also do some prep, and the plumbers will replace a section of old drain line in a closet soffit.

Be sure to visit our facebook page for regular updates and photos on this project.

Have a wonderful week,

The Myers Constructs Team

Revisit previous updates on this project:

Step 1: Planning

Step 2: Demolition

Step 3: Insulation and Framing

Step 4: Prepping for Inspection

Step 5: Pre-Closing

Step 6: Drywall