The Details That Matter

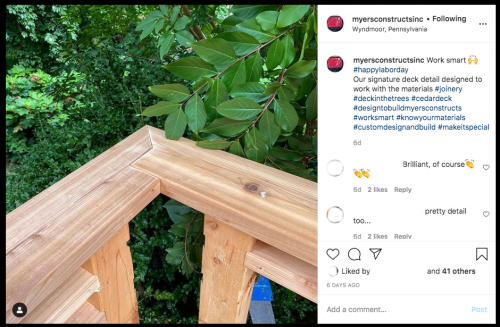

You may recognize this deck image from our Facebook and Instagram accounts last week. It was a popular post that generated a lot of questions and interest, so we thought we’d share the backstory with you.

We came up with this little railing detail maybe 20 years ago, and we now use it on all of our decks because it’s a superior solution. Here’s why.

When you work on older houses, you have to take things apart as a part of renovating. You see what worked and what did not, and how long it lasted. You see how the people who did a section of work maybe 10, 20, or even 100 years ago thought about how to put something together — and they set you up to be able to fix it easily when it finally wore out. We always notice this, and we think about those people, who may no longer be alive, but we hope they hear us thanking them.

You also see what didn’t last or work at all, like renovation “coverups.” Maybe an old plaster wall was peeling a little paint or had a crack in it, and instead of repairing it properly, workers just layered over some paper or paneling. Then that failed a few years later, and they added another layer of something. Finally, we come in and fill a dumpster with all of the layers we need to remove just to get back to the nice plaster so we can finally repair that little crack or missing section. It’s a wasteful use of resources and time.

Inferior materials and quick-fix solutions simply don’t last. We’ve had to pull out almost every 1980s kitchen or bathroom we’ve ever seen because the materials and construction methods were not of good quality during that time. The big box stock cabinets get wet, swell, and deteriorate very quickly — they don’t even get old enough to wear out. Meanwhile we see 100-year-old bathrooms still working. The wall tile might have a thin settling crack, or the lead drain may finally have given up, but for the most part, the fixtures and finishes are still working. That’s pretty remarkable.

In working on decks over the years, we’ve seen that simple 45-degree corners on railings always open up after a certain point. So we came up with our solution that is a combination of a butt joint and a mitered joint that has more attachment surfaces and less area to open up. It’s not much harder to do than a simple 45-degree joint, but it performs substantially better. It has since become a calling card of sorts for us.

Tamara and I want to be like the builders of those 100-year-old bathrooms. We want to build projects right the first time so they last. Sometime in the future, some other carpenter will come along to replace the worn out railing we put in, and they will thank us for making their job easier for them. And in the meantime, our clients will “spend once.” They won’t have to repair that capping anytime soon.